Sepiolite, also known as meerschaum, is a mineral with intriguing physical and chemical properties. In addition to its characteristic fibrous structure, sepiolite exhibits a range of colors including white, light gray, and light yellow. Its opaque and lustrous appearance adds to its aesthetic appeal. One interesting feature of sepiolite is its diverse morphology; while some specimens resemble clods of dirt in shape, others exhibit peculiar crust or tubercle formations. Under the lens of an electron microscope, these structures reveal numerous filaments clustered together in sheets.

The most intriguing property of sepiolite lies in its interaction with water. When exposed to moisture, sepiolite has the ability to absorb significant amounts of water and become soft and pliable; however, upon drying out completely it regains its original hardness once again. This unique behavior can be attributed to the layered chain structure present within sepiolite crystals which are formed by interconnected magnesium silicate units that create channels capable of accommodating water molecules during hydration processes.

Due to this distinctive structure, sepiolite possesses excellent adsorption properties which enable it to effectively trap various substances within its porous network when in contact with liquids or gases making it useful for applications such as environmental remediation and purification processes. Furthermore, sepiolite exhibits remarkable rheological properties which refer to how it behaves under stress or deformation forces; its fibrous nature allows for flexibility while maintaining structural integrity even under pressure or mechanical strain.In addition to adsorption and rheological characteristics mentioned above,sepiolite also displays catalytic properties due to the presence of active sites on the surface enabling it facilitate chemical reactions by lowering activation energy barriers.

Sepiolite is a magnesium-rich silicate clay mineral with a theoretical chemical formula of Mg8[Si2O30](OH)4·12H2O. The SiO2 content generally ranges between 54% and 60%, while the MgO content falls within 21% to 25%. It often contains trace amounts of iron, manganese, and other elements. Sepiolite exhibits variable colors, typically appearing as light white or gray but also displaying shades of light gray, dark gray, yellow-brown, rose red, and light blue-green. Its opacity also varies. The fresh surface has a pearly luster while the weathered surface appears earthy. It feels smooth and sticky to the touch and has a hardness rating of 2-2.5 on the Mohs scale. With a specific gravity ranging from 1 to 2.3, sepiolite can absorb over 150% of its own weight in water. Furthermore, it maintains its structural integrity at temperatures up to 350 degrees Celsius and exhibits high temperature resistance reaching levels between 1500°C and1700°C.

The genesis of sepiolite deposits can be classified into two types: eluvial hydrothermal and sedimentary. Sepiolite is a rare non-metallic mineral with limited distribution in nature, primarily found in Spain, China, the United States, Turkey, and a few other countries. According to available data, the current proven reserves of sepiolite worldwide are approximately 80 million tons, with potential reserves likely to be much larger. Spain has proven reserves of 38 million tons while China has proven reserves of 26 million tons; together these two countries account for 80% of the global proved reserves.

Sepiolite is extensively used in catalysis and represents a well-established application technology. It possesses commendable adsorption properties, a substantial specific surface area, and significant acidity and alkalinity levels, thereby exhibiting certain catalytic effects while also facilitating synergistic catalysis with the catalyst itself. As a carrier, sepiolite can effectively support active components such as Zn, Cu, Mo, W, Fe, Ca, and Ni for demetallization processes like deasphalting, hydrodesulfurization, and hydrocracking. Currently employed preparation methods for sepiolite-supported catalysts include the hydrothermal reduction method, microemulsion-sepiolite infiltration method as well as immersion reduction method.

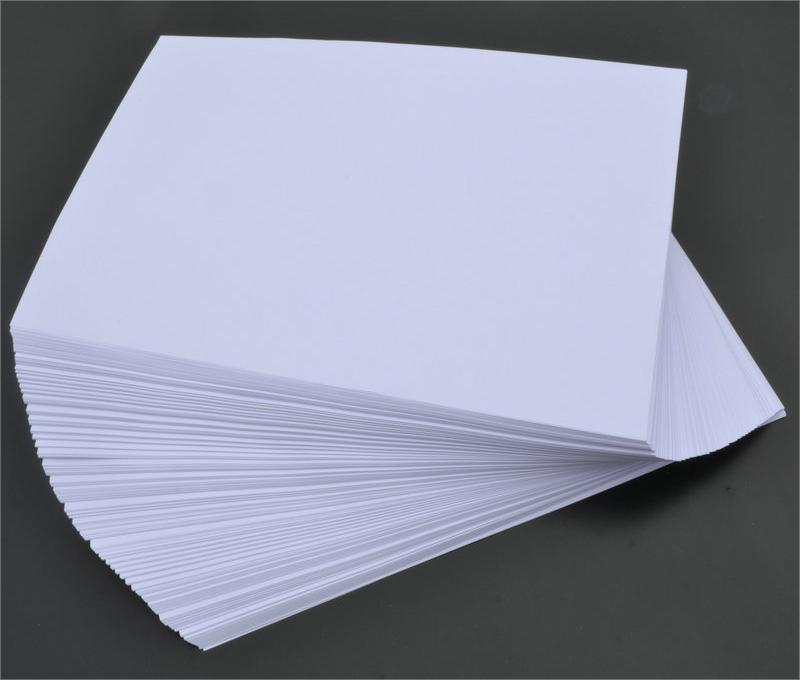

Corrected sentence: Sepiolite is extensively used in the paper industry due to its properties, including adsorption, flame retardancy, high-temperature resistance, and wear resistance. It provides new uses and functions for paper products. Sepiolite’s absorbency can be utilized to produce liquid filter paper, environmentally deodorizing paper, cigarette filters, color coatings in carbon-free carbon paper, highly absorbent layer diaper papers, sanitary napkins and moisture-absorbent papers. Its flame retardancy, high-temperature resistance and wear resistance make it an ideal material for insulation layers in fire protection equipment such as mats used in motor vehicles or household appliances like microwave ovens or electric stoves. Additionally, it can also be employed to produce flame-retardant wallpaper for senior hotels and restaurants.

The unique layered structure and vast specific surface area of modified sepiolite contribute to its exceptional adsorption capabilities and significant ion exchange capacity, making it an ideal choice for environmental pollution control.

One of the key advantages of utilizing modified sepiolite lies in its robust adsorption ability, enabling effective removal of various pollutants from wastewater, including heavy metals, organic compounds, and even pathogens. By capturing these contaminants on its surface or within its porous structure, sepiolite aids in water purification and reduction of harmful substances.

Furthermore, the substantial ion exchange capacity exhibited by modified sepiolite enhances its efficacy in sewage treatment processes as it can replace unwanted ions with more desirable ones through ion exchange reactions. This property enables sepiolite to eliminate excess nutrients such as phosphates or nitrates from wastewater, preventing eutrophication and maintaining ecological balance in aquatic environments.

Agricultural pesticides pose certain limitations in pest elimination methods currently mastered by individuals due to prolonged use of insecticides resulting in pest resistance development. To ensure both efficacy and safety, researchers have developed a modified sepiolite as a carrier for myithrin, permethrin, and DEET insecticides. This advancement is crucial for prolonging the effectiveness of these insecticides.

Feed additives play a vital role in animal husbandry where sepiolite is widely used as an affordable and efficient option. The particles of sepiolite aid in evenly distributing essential components like vitamins, minerals, and antibiotics throughout the feed while also preventing any potential interference between absorbed vitamins/minerals with trace elements or their absorption.

Edible oil decolorization and refining. Unprocessed rapeseed oil available in the market often exhibits a dark color along with high aflatoxin content, resulting in excessive smoke during usage. The decolorizing effect achieved through sulfuric acid-activated sepiolite surpasses that offered by domestically produced activated clay products. Consequently, it can be employed as a novel decolorizing agent for vegetable oils.

What is Sepiolite and Sepiolite Grinding Mill" title="What is Sepiolite and Sepiolite Grinding Mill-Raymond mill, Raymond roller mill can be used in more than 300 kinds of minerals powder grinding, Shanghai Clirik YGM Raymond Mill" >

What is Sepiolite and Sepiolite Grinding Mill" title="What is Sepiolite and Sepiolite Grinding Mill-Raymond mill, Raymond roller mill can be used in more than 300 kinds of minerals powder grinding, Shanghai Clirik YGM Raymond Mill" >Capacity: 0.2-45 t/h

Feed Size: ≤20 mm

Powder Fineness: 325-3000 mesh

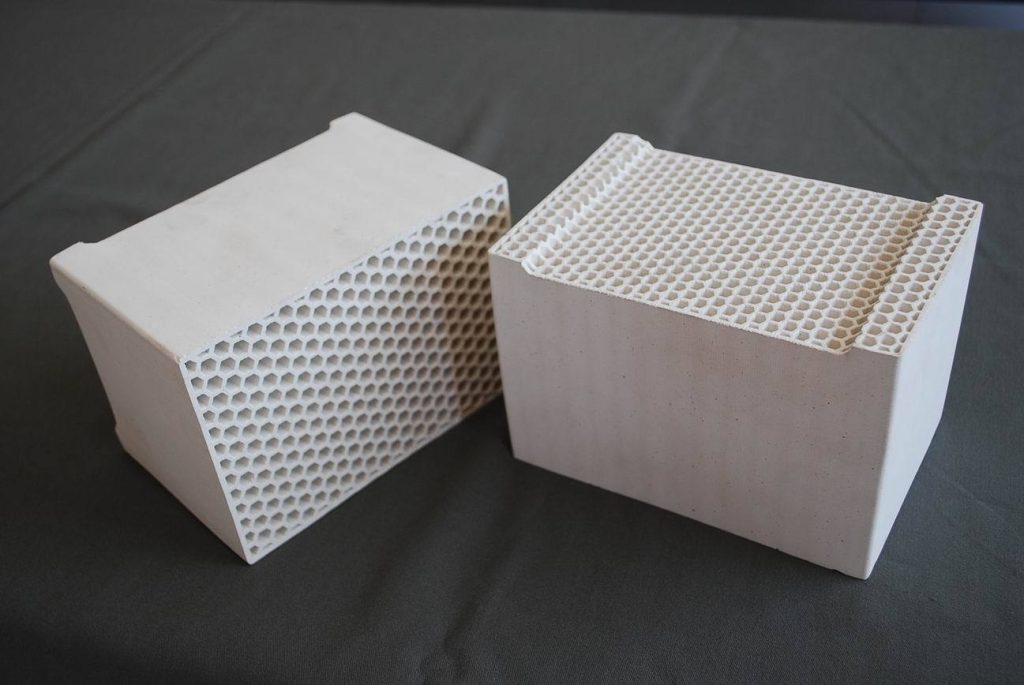

The HGM series ring roller mill is a novel type of ultrafine grinding equipment developed by Clirik after years of extensive research and development, incorporating the advantages of existing ring roller mills in the market. The HGM series ultrafine grinding machine boasts high productivity, low energy consumption, economical production costs, and easy maintenance. It stands as the epitome of dry ultrafine grinding equipment in China.In terms of structure, the HGM series ultrafine mill adopts an impact-extrusion-grinding principle to effectively crush materials.

Compared to similar products available in China, this mill features a combined grinding pair structure and a transmission spindle with a multi-angle diamond design. These enhancements contribute to its exceptional crushing capacity, reduced maintenance requirements, and lower operational expenses.Primarily designed for crushing brittle materials with a hardness level below 6 (such as heavy calcium minerals like calcite, marble, dolomite), barite, talc gypsum petroleum coke carbon black magnesite aluminum hydroxide white powder wollastonite kaolin bentonite rare earths), the HGM series ultrafine grinding machine excels at delivering superior performance while maintaining cost-effectiveness.

Enhanced Productivity: The innovative roller design and rational material selection not only enhance the robustness and reliability of the grinding machine but also increase the grinding pressure on processed materials by approximately 15%-20%. This leads to improved productivity and efficiency, enabling faster processing of materials.

Extended Lifespan: With reduced bearing replacements required and a longer service cycle, this grinding machine boasts a lifespan that is 3-5 times longer than other similar machines. This results in reduced maintenance costs and increased operational uptime, ultimately leading to higher overall productivity.

Precise Discharge Control Made Easy: The powder sorting machine, equipped with frequency-adjustable speed, enables efficient operation and precise control over discharge fineness. This ensures consistent quality output while meeting specific requirements for different applications.

Energy Efficiency at its Best: By incorporating a new type of high-efficiency pulse dust removal equipment along with noise reduction devices, this grinding machine effectively eliminates dust, noise pollution, and other environmental hazards associated with traditional models. It promotes green production practices by creating a cleaner working environment.

Cost-effective Solution: In addition to its numerous advantages mentioned above, this grinding machine offers significant price concessions compared to gas mills or alternative options in the market. Despite providing the same capacity and fineness levels as its counterparts, it is priced more than 80% cheaper – making it an affordable choice without compromising performance or quality.

Clirik is a reputable manufacturer of mining machinery and equipment, renowned for their global popularity. If you have any interest in our top-notch equipment, please feel free to contact us using the information provided on this page. Moreover, we boast a team of highly skilled engineers and technicians who are capable of tailoring machinery and equipment to meet your specific requirements, ensuring that they perfectly suit your needs. We eagerly await your call!